Castle Run is an innovative tool of simulation for die casting process: quick (model preparation and simulation require only a few minutes) and reliable, it allows the tooling designer to verify the runner system geometry without the need to run the simulation of the entire part and then to analyze and validate multiple alternative solutions to achieve all the goals of a good runners design: capability to fill in the cavities at requested speed and time, no turbulences etc.

Castle Run is an innovative tool of simulation for die casting process: quick (model preparation and simulation require only a few minutes) and reliable, it allows the tooling designer to verify the runner system geometry without the need to run the simulation of the entire part and then to analyze and validate multiple alternative solutions to achieve all the goals of a good runners design: capability to fill in the cavities at requested speed and time, no turbulences etc.

- Runners design quick evaluation

- Optimization of runners geometry

- Model preparation and calculation in a few minutes

- Multiprocessing and cloud computing calculation

- Control of gates proper working and metal entry angle into the die cavity

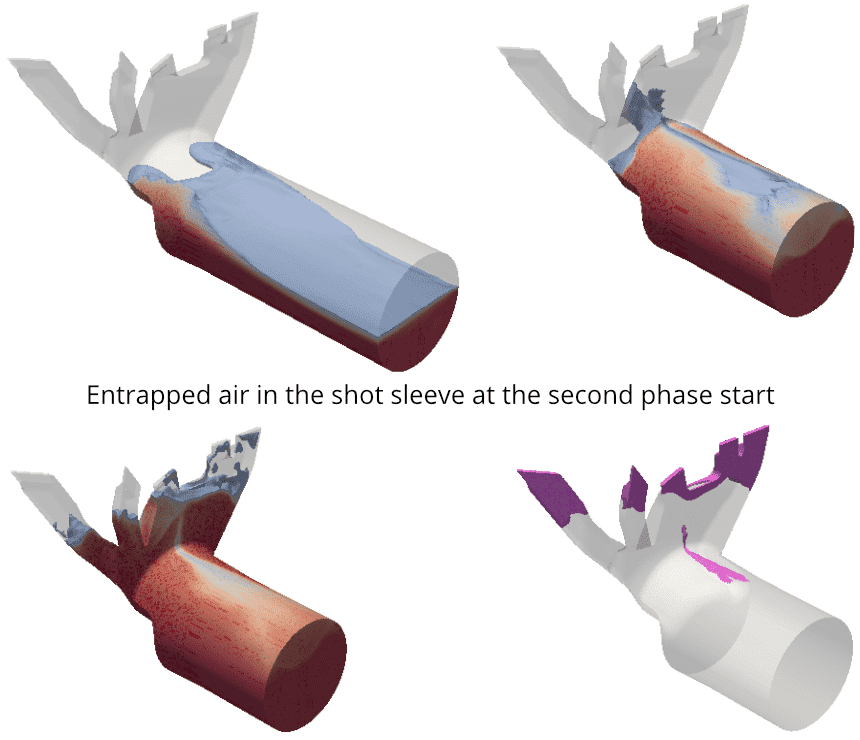

- First phase injection curve optimization

- Free viewer

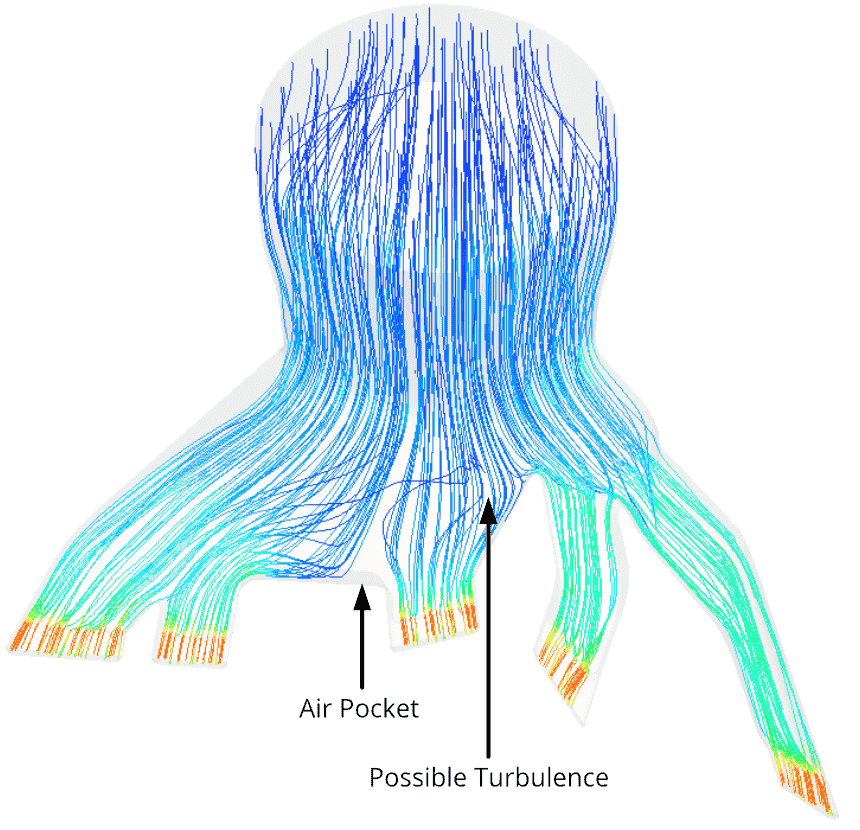

In details Castle Run, through a complete map of pressures and velocities, is able to investigate:

- Flow turbulences, air entrapments, energy drops by friction and fluid vein reductions.

- Extreme velocity at the gates may lead to die erosion and metallization

- Whether the molten metal enters into the cavity through the entire section of the gate or alternatively there are gate areas “not properly working”, such as not correct flow balance among multiple gates.

- The direction of the metal entry vectors. It allows to identify the main flow direction into the cavity which can be canalized where requested.

- Through easy CAD tools of analysis and blend radii management the user is allow to edit the runner design in real time until the final requested geometry is achieved.