Castle Body is an innovative software solution that presents a very advanced mathematical feature in the field of the applications for die casting: the capability to simulate the combined action of a liquid (the metal) and a gas (the air), one uncompressible and the other compressible with very different densities. This feature allow to reach uppermost accuracy levels, including the capabilities to evaluate the effect of the metal spraying and to analyse the physics of the vacuum effects and of the vents.

Castle Body is an innovative software solution that presents a very advanced mathematical feature in the field of the applications for die casting: the capability to simulate the combined action of a liquid (the metal) and a gas (the air), one uncompressible and the other compressible with very different densities. This feature allow to reach uppermost accuracy levels, including the capabilities to evaluate the effect of the metal spraying and to analyse the physics of the vacuum effects and of the vents.

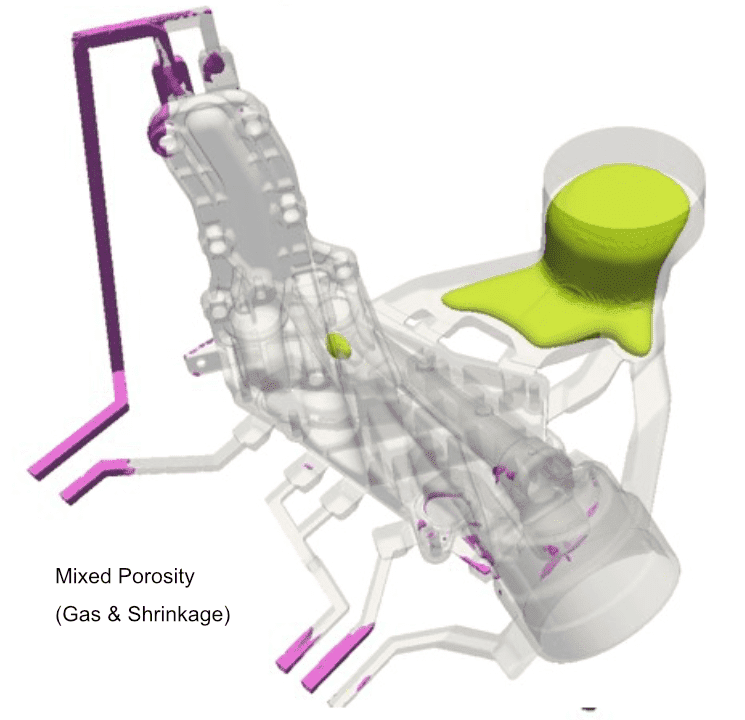

- Filling and Solidification analyses

- Direct file import from a variety of CAD systems

- Model preparation and calculation input in a minute

- Multiprocessing and cloud computing calculation

- Unlimited number of processors without cost

- Dual Phase: combined metal flow and air simultaneously analyzed

- Very realistic simulation of metal filling which takes in consideration the action of vacuum and vents.

- Free viewer

Thanks to integration with Castle Mind the process conditions set by the simulation are as much realistic as possible (including the real injection velocity curve) and it allows to achieve a simulation which is a very good representation of the real process. It is useless and misleading to simulate a process with conditions which are different from the real ones.

Thanks to integration with Castle Mind the process conditions set by the simulation are as much realistic as possible (including the real injection velocity curve) and it allows to achieve a simulation which is a very good representation of the real process. It is useless and misleading to simulate a process with conditions which are different from the real ones.

The calculation engine is combined with a very simple and essential user interface and both data input and results visualization are expressed in a way that makes every operation easy and comprehensible even for operators without a technical background. It is possible to prepare the simulation to launch in a few minutes starting from every kind of geometries and the 3D mesh calculation takas automatically in consideration the areas where it is necessary a refined mesh (i.e. the gates) and areas rougher (i.e. the plunger).

The calculation engine is combined with a very simple and essential user interface and both data input and results visualization are expressed in a way that makes every operation easy and comprehensible even for operators without a technical background. It is possible to prepare the simulation to launch in a few minutes starting from every kind of geometries and the 3D mesh calculation takas automatically in consideration the areas where it is necessary a refined mesh (i.e. the gates) and areas rougher (i.e. the plunger).

The source code splits (without any additional cost) the calculation into the processing units of the computer (the number of units is set by the user) and it is also able to utilize other hardware resources along the network through the cloud computing. Practically speaking it means an important saving of calculation time and the possibility for the user to achieve more comparative simulations in reasonable industry times.

The source code splits (without any additional cost) the calculation into the processing units of the computer (the number of units is set by the user) and it is also able to utilize other hardware resources along the network through the cloud computing. Practically speaking it means an important saving of calculation time and the possibility for the user to achieve more comparative simulations in reasonable industry times.